Samples made according to your requirements We will seal the samples after your confirmation. All subsequent production will follow this confirmed sample.

Applying established workflows and practices based on industry standards,

our manufacturing process ensures that every step we take is foolproof and has traceable data. Our focus on quality results in the best possible quality

and yield for each project.

Samples made according to your requirements We will seal the samples after your confirmation. All subsequent production will follow this confirmed sample.

Before all raw materials are put into storage, our quality inspectors will check them to ensure that the color, quantity and material of these raw materials are consistent with your order.

Highplus introduces an international standard production process. Each process has a production manual, which describes the process requirements of the project currently being produced by employees, including pictures, process names, material specifications, process control points and self-inspection standards.

After the sewing process is completed, the product will enter the quality inspection workshop of the finished product through the needle testing machine. Needle detectors can ensure that the products delivered to customers are free from broken needles and metal debris, ensuring the safety of consumers.

Before the product is delivered, we will check the product packaging to ensure that the packaging is in accordance with your packaging requirements and nothing is missing.

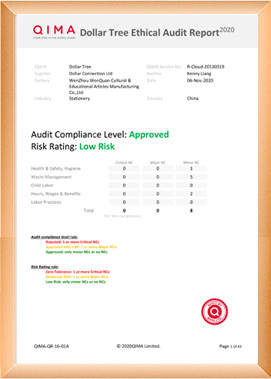

Highplus has obtained important certifications and recognitions from authoritative organizations, such as: BSCI, DT ETHICAL AUDIT, FSC, etc.

GET A QUOTE